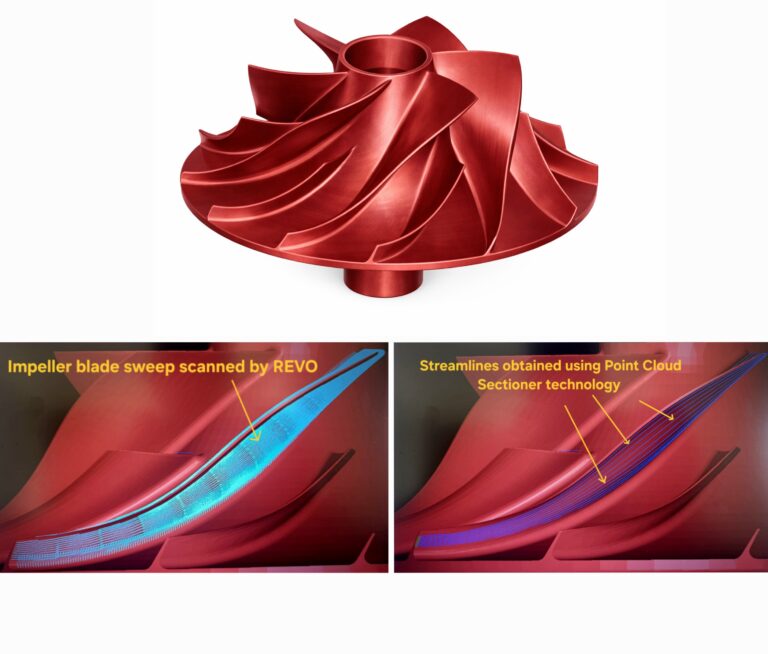

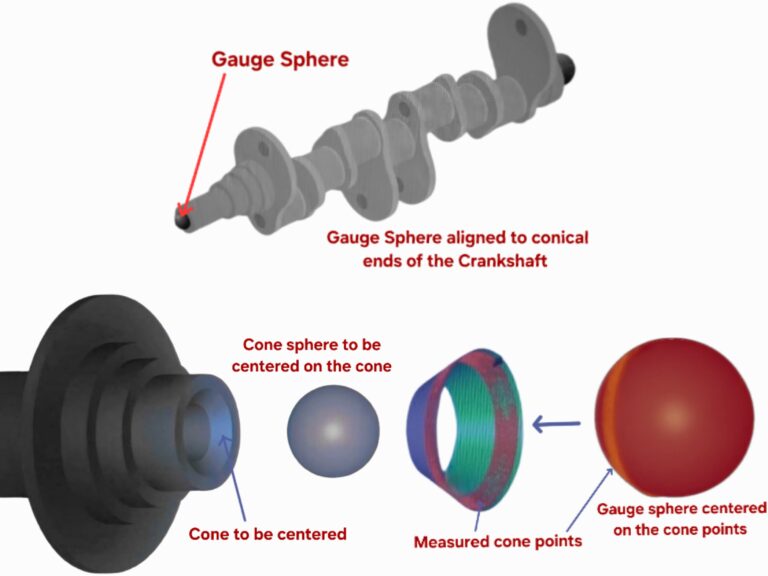

Reliable method to extract very small features from measured data

Challenge

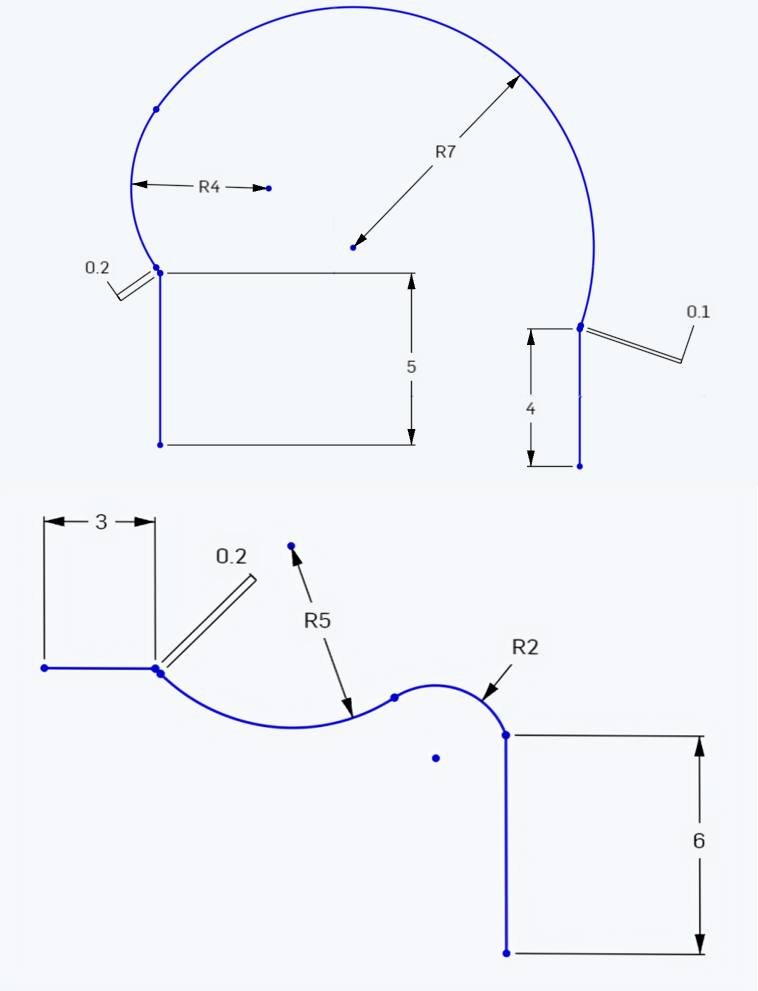

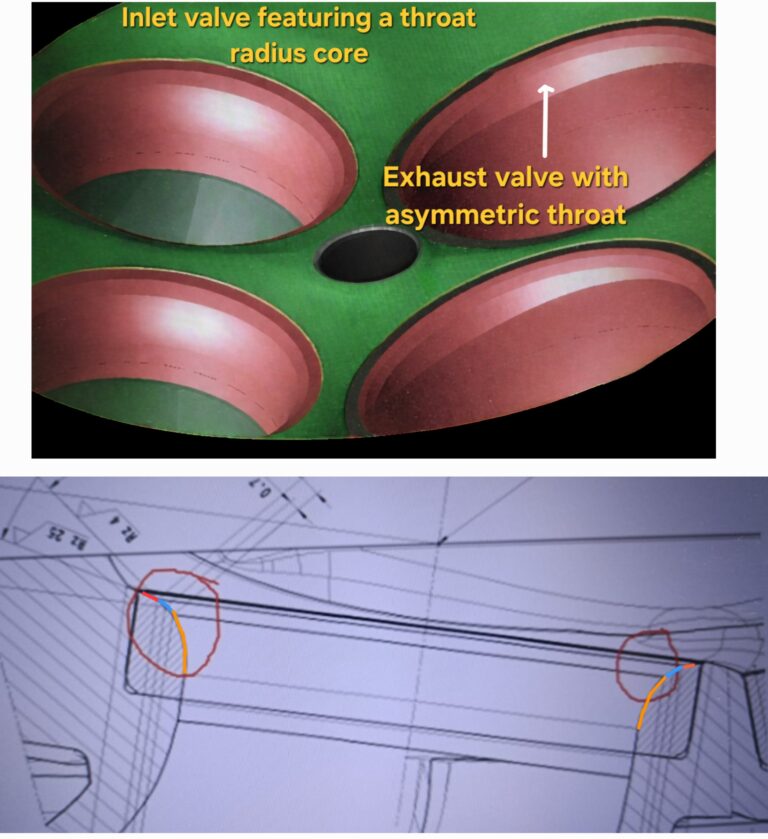

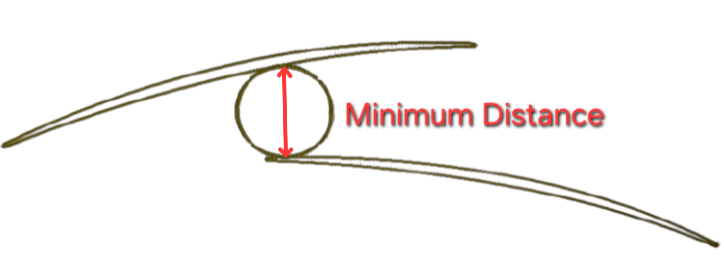

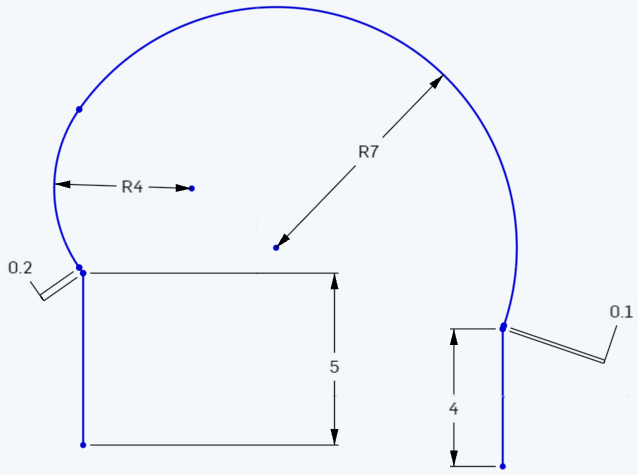

To extract the actual dimensions of very small features connected to other features within a continuous measured dataset. These features, in the range of 100 to 150 microns, were almost impossible to extract using traditional techniques, such as a chamfer or fillet about 100 microns in size.

Solution

A single continuous scan was performed, capturing multiple features simultaneously. The features of interest were then mathematically extracted from the measured data using intelligent data fitting.

Business Impact

Many major international companies adopted this solution across China, Europe, and the USA. It helped us engage with key customers, driving hardware sales of nearly 25 million dollars and strengthening long-term customer relationships.

“Thanks for follow it up. With your support, we have measured those critical features and pass the GRR. The program itself is currently running at customer site and considered as a success. We would not be able to reach to this point without your team’s support. I would like to send our thanks to you and your team for your excellent support.”

Technical Sales & Marketing

Hong Kong